horizontal ball mill pdf

2017-03-01T03:03:35+00:00

689+

производственное

оборудование

170+

страна

обслуживания

3200

численность

персонала

180+

государственный

патент

horizontal ball mill pdf

ScienceDirect

Design of horizontal ball mills for improving the rate of

2021年3月1日 The objectives of the present study were to: i) develop a model of horizontal ball mill by Solidworks and calculate collision energy by DEM simulation; ii) optimize the

(PDF) Grinding in Ball Mills: Modeling and Process

2012年6月1日 PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding

[PDF] Fine grinding in a horizontal ball mill Semantic Scholar

2007年4月1日 Fine grinding in a horizontal ball mill @article{Partyka2007FineGI, title={Fine grinding in a horizontal ball mill}, author={Trish Partyka and D Yan}, journal={Minerals

Design of horizontal ball mills for improving the rate of

DOI: 101016/jpowtec202011069 Corpus ID: ; Design of horizontal ball mills for improving the rate of mechanochemical degradation of DDTs

Ball milling: a green technology for the preparation and

Ball milling is a simple, fast, costeffective green technology with enormous potential One of the most interesting applications of this technology in the eld of cellulose is the

Horizontal roller mill (Horomill®) application versus hybrid HPGR/ball

2009年12月1日 Introduction Section snippets References (8) Cited by (15) Minerals Engineering Volume 22, Issue 15, December 2009, Pages 13441349 Horizontal roller

Design of horizontal ball mills for improving the rate of

2021年3月1日 The objectives of the present study were to: i) develop a model of horizontal ball mill by Solidworks and calculate collision energy by DEM simulation; ii) optimize the

フィールド Horizontal Ball Mill Yokogawa

2020年4月11日 Introduction horizontal rotary miller used to grind the limestone rocks with metallic balls as grinding stones This is used as the raw ingredient to produce cement

Horizontal roller mill (Horomill®) application versus hybrid HPGR/ball

2009年12月1日 Horomill ® This study presents the size reduction efficiencies and specific energy consumptions of an industrial scale Horomill ® and Hybrid HPGR/two

Influence of ball size distribution on grinding effect in horizontal

2014年5月1日 The law of ball size distribution in the horizontal planetary ball mill is studied by the discrete element method The results show that the maximum impact energy

High dispersibility of αAl2O3 powders from coprecipitation

2017年7月18日 αAl2O3 powder is widely used in numerous applications, especially in optical ceramics and crystals growth However, achieving perfect dispersibility is essential in these applications and requires a complete understanding of the dispersion mechanism as well as high technology processing In this paper, a stepbystep horizontal ballmilling

Design and Analysis of Ball Mill For Paint Industries IJSRD

2014年10月10日 apply All ball mills consist of rotating cylinders that contain hard (usually metallic) balls that do the grinding A Horizontal Ball Mills: Horizontal ball mills are the most common type The basic design is the same but the details can vary slightly A drum, which is usually detachable, has a door that can be used to

Roller Mill Based on Experimental Method mdpires

2022年1月23日 and vertical roller mill ie, VRM [3–5] Among these devices, VRM plays an important role in cement, accounting for more than 55% of China’s cement raw meal market [6], and its performance directly affects the cost of producing cement VRM has the functions of grinding and powder selection, including a grinding unit and an air classifier

Ball mill Superior cement quality, More fl exibility, higher

2020年9月22日 end product specifi cations and drive type The horizontal slide shoe bearing design enables much simpler foundations and reduced installation height, making installation quicker and less expensive The entire mill is protected with bolted on lining plates designed for the specifi c wear faced by each part of the mill ball mill

Influence of ball size distribution on grinding effect in horizontal

2014年5月1日 The law of ball size distribution in the horizontal planetary ball mill is studied by the discrete element method The results show that the maximum impact energy could be acquired when filling

Horizontal roller mill (Horomill®) application versus hybrid HPGR/ball

2009年12月1日 They were introduced in 1993 at Buzzi Unicem’s Trino plant in Italy with the purpose of reducing energy costs Details of the operating principle of Horomill ® as compared to HPGR and vertical roller mills are given by Cordonnier (1994) and Buzzi (1997)The energy saving of this mill is claimed to be similar to that of HPGR and

Mathematical validation and comparison DOI

2023年6月10日 vertical spindle bowl mill expressing the accuracy of mill operations during startup, shutdown and normal states Niemczyk et al [8] validated the steady state model against data from two distinct plants, one having ball and race mill and the other having vertical roller mill indicating its reliability Model coefficients

[PDF] Fine grinding in a horizontal ball mill Semantic Scholar

2007年4月1日 Semantic Scholar extracted view of "Fine grinding in a horizontal ball mill" by T Partyka et al Has PDF Author More Filters More Filters Filters Improving fines recovery by grinding finer J Pease M Young D Curry N Johnson Materials Science 2004; Abstract It is commonly believed that fine particles have low flotation recoveries

Ball Mill an overview ScienceDirect Topics

A ball mill consists of a hollow cylindrical chamber (Fig 62) which rotates about a horizontal axis, and the chamber is partially filled with small balls made of steel, tungsten carbide, zirconia, agate, alumina, or silicon nitride having diameter generally 10 mm The inner surface area of the chamber is lined with an abrasionresistant

Mill lining solutions for horizontal Metso

2021年8月11日 • Metallic mill linings • Skega™ PolyMet™ mill linings • Skega™ rubber mill linings • Orebed™ mill linings • Megaliner™ Liners for all types of mills Our stateoftheart linings are available for mills of virtually all types, sizes and brands • Semiautogenous mills • Fully autogenous mills • Ball mills • Rod mills

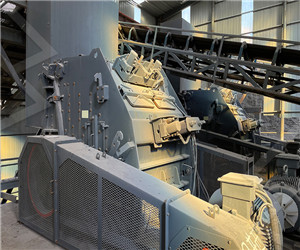

Ball Mills PSP Eng

2016年5月4日 Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials PSP Engineering has continuously refi ned the design of its ball mills Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearings

(PDF) Fine grinding in a horizontal ball mill Academia

At grind sizes below 20 to 30 μm, ball mills become inefficient (Yan et al, 1995) and steel media contamination is a problem Iron contaminates the ground product and starts to alter the chemistry of the next unit operation – be it leaching or flotation (Pease et al, 2004) Because of this, grinding below 25 μm in a horizontal ball mill is

Stirred Mill an overview ScienceDirect Topics

Stirred Mills – Ultrafine Grinding In Mineral Processing Design and Operations (Second Edition), 2016 1024 Operation of Vertical Mills Vertical stirred mills are usually charged with media occupying 80% of the mill volume which is in sharp contrast to tumbling mills that are seldom charged more than 40% of their volumes to allow space for the tumbling

行星式球磨仪PM100德国RETSCH(莱驰)研磨仪粉碎仪

Download The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg It allows for grinding up to 220 ml sample material per batch The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and

Select™ Horizontal Grinding Mills Metso

The Select™ horizontal grinding mills simplified and preengineered selection process provides multiple benefits This includes: Cost savings from investing in a preengineered solutions, time savings from our expedited selection, quotation process, and order execution, and faster delivery and startup of your Select™ horizontal grinding

Horizontal roller mill (Horomill®) application versus hybrid HPGR/ball

2009年12月1日 Introduction Conventionally multicompartment ball mills are used in finish grinding of cement However, they are relatively inefficient at size reduction and have high energy consumption, so it is increasingly common to find grinding technologies such as High Pressure Grinding Rolls (HPGR), vertical mills and Horomill ® in cement plants As

Study of Hammer mill and Ball mill Centurion University

2020年6月23日 Ball mill is a type of crusher, is a cylindrical device used to grind or mix materials like ores, chemicals, ceramics and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used for media, including ceramic balls, flint pebbles and stainless steel

Ballmilling ResearchGate

Ball mill is crucial to numerous industries as an equipment for producing extremely crushed materials, eg cement, refractory materials, fertilizers, glass ceramic, ore dressing of ferrous as

The design and optimization process of ball mill to reduce

2020年11月16日 The balls to powder ratio (BPR) and powder type were investigated in relation to the particle size The study showed that the combination of the BPR and powder type affects the particle size result The optimum of BPR at 12 with the number of balls is 60 pieces, and the filling rate is 1013% The result shows that the horizontal ball mill able

(PDF) Cements ground in the vertical roller mill

2013年3月1日 C Obry KarlHeinrich Zysk Vertical roller mills are the mills traditionally used for processing granulated blastfurnace slag and for grinding composite cements From the energy aspect they are

CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS

2022年7月26日 In a ball mill, the particles are ground by repeated impact forces The material usually needs more than 20 minutes of grinding from mill entrance to outlet, with uncountable impacts take place on this way Depending on the efficiency of the separator and the Grinding Aid, agglomerates of fine particles are rejected and pass the ball mill

Ball mill for cement grinding

Cement grinding with our highly efficient ball mill An inefficient ball mill is a major expense and could even cost you product quality The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance With more than 4000 references worldwide, the ball mill is

Kinematic observations and energy modeling of a Zoz

2013年8月4日 Planetary and horizontal ball mills, attritors, 1D and 3D vibrating apparatus are wellknown and utilized in this powderprocessing technology This paper is focused on a ZOZ Simoloyer CM01 horizontal ball milling apparatus; a kinematic model characterizing balls motion and energy released have been found

(PDF) Effects of Ball Size Distribution and Mill Speed and

2020年7月2日 In recent research done by AmanNejad and Barani [93] using DEM to investigate the effect of ball size distribution on ball milling, charging the mill speed with 40% small balls and 60% big balls

Fine grinding in a horizontal ball mill ScienceDirect

2007年4月1日 Introduction As coarse grained, easily processed ore bodies are depleted, more disseminated, finegrained ores are being treated Adequate liberation of valuable components within a finegrained ore is often only achieved once the particle size of the ore has been reduced to levels below the traditional ball mill cutoff of 45 μm To aid in the

(PDF) Process Engineering with Planetary Ball Mills

2013年2月7日 Various devices have been used for processing B powder, including attritor mills, conventional planetary mills, tumbler mills/mixers, vibratory mills, shaker mills, and uniball mills [161][162

Numerical simulation of ball milling reactor for novel

2023年1月15日 An interesting topic of this simulation method is the issue of correctly reproducing a planetary ball mill for ammonia synthesis using DEM This simulation is mainly focused on the impact of the ball and particle, the contact between the particle and the ball along with the wall of the mill, which results in the production of all the energy of the

Failure analysis of a ball mill located in a cement’s

2022年8月1日 The ball mill understudy has a length of 1307 m in its cylindrical geometry and a length between supports of 162 m (Fig 1 a,b)The formation of cracks in the middle span has been identified, generally spreading from the holes near the maintenance manhole, as shown in Fig 1 c Certified welders carry the repairing procedure using

® Tower Mill A vertical leap in fi ne grinding

2021年9月13日 feature of the tower mill is a central agitator screw, the only moving machine component in contact with the slurry and steel media, which allows size reduction by attrition This arrangement reduces energy consumption in fine grinding of minerals by 25% to 50% when compared to traditional horizontal ball mills for the same feed and